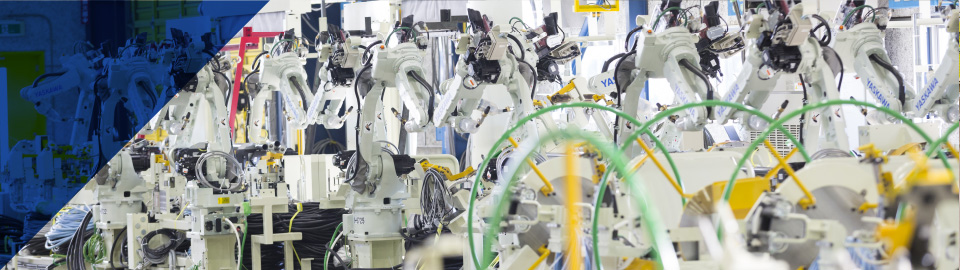

Design and technical capabilities for the manufacture of custom-made machines to meet the needs of our customers.

Our policy from our founding days to “keep running at the cutting edge” is still applied to our various business operations in introducing the latest machines and systems. In our business of custom made machines, we continue to meet the challenges of the global market by manufacturing custom-made machines which completely satisfy the customer needs.

Strengths of our Custom made machines Division business

Latest front-loading design

We have introduced 3D tools such as CAD, 3D simulators and 3D printers ahead of the industry and thus achieved cost reductions by speedy design and improvements in our proposal capabilities. We have accumulated a wealth of technical expertise cultivated through integrated in-house processes of design, processing, manufacture and adjustment, which affords us the total planning ability to accurately respond to our customer needs.Production capacity and technical capabilities

We are proud of our capacity to cater to various design specifications, order quantities and desired delivery dates. We can visualize the assembly, adjustment and complete installation of the machinery at the customerʼs site, which leads to feed-back for future projects. Over 90% of our staff are certified technicians, which underscores our attitude toward technical enhancement.Built-to-order machines of high difficulty

We not only flexibly respond to the customer needs but also propose ideas for improvement based on our technical know-how established over many years of manufacturing. Utilizing our technical capabilities in building machines, from the planning and design stages and ranging from single units to large production lines, we pay attention to all details in manufacturing one-of-a-kind, custom-built machines.Our highly rated total planning technical capabilities

Our total planning service encompasses the system-building processes of verification by simulations utilizing 3D tools, designing, processing, assembly, test running, installation and maintenance. We carry out all processes for the production and installation of custom made machines built to meet customer needs while coordinating the flow between these processes. Our integrated system for development, proposal and maintenance enables us to totally guarantee high production quality, optimal prices and delivery time, and has been highly rated by major manufacturers such as Denso and Toyota. We have also developed and introduced our original electronic system “F-DAM” which improves the efficiency of design work and precision in information sharing with our overseas production locations.

Establishing one-of-a-kind production system with wide-ranging capacity and technical capabilities

We flexibly and widely handle the various specifications requested uniquely by each of our customers, including major automobile manufacturers and other industries, and have the design and proposal capabilities for building automated and rationalized production lines. We have been highly praised for our capacity to cater for new car models or products with our rich technical know-how and large-scale production line orders. We will continue to challenge ourselves in producing machines of high difficulty and one-of-a-kind machines by sharing cutting-edge production technologies with the major manufacturers who order directly from us.

Strengthening the ability to make proposals

Fuso Machine Works is “aiming at the cutting edge of industry” by proactively introducing the latest facilities and systems. We are endeavoring to reduce delivery periods and costs by standardizing the custom made machines Division and to expand our general know-how by receiving more production line orders, and thereby further refine our proposal capabilities to respond to the development of new fields and the shift to electric cars. We are also strengthening our global deployment by providing technical support and facility upgrades at our overseas bases in order to establish a system for assisting our customersʼ overseas business expansion. Whether domestically or overseas, we are meeting the challenge for even higher levels of custom-made machine manufacture with our established know-how and facilities.